Hot vs. Cold Applied Traffic Paint: The Ultimate Guide

Choosing the right road marking material is a critical decision that impacts public safety, project budgets, and long-term maintenance. Traffic paints are broadly categorized into two main types based on their application method: cold applied and hot applied (thermoplastic). Each category offers distinct advantages in terms of durability, cost, and use-case suitability.

Cold applied traffic paints are generally more economical and easier to apply, making them an excellent choice for low-traffic areas and projects with budget constraints. In contrast, hot applied traffic paints, also known as thermoplastics, offer superior durability and a much longer lifespan, making them the standard for high-traffic highways and major roadways where longevity is paramount.

Understanding the factors that influence this choice is key to a successful and cost-effective project. This guide will provide a comprehensive comparison of hot and cold traffic paints to help you make an informed decision.

Key Factors in Choosing Traffic Paint

Before diving into the specific types of paint, it's essential to assess the unique requirements of your project. Ask yourself the following questions to determine the best material for your needs.

1. What Level of Durability is Required?

The longevity of your road markings is paramount. Consider the location: is it a high-traffic interstate, a busy parking garage, or a quiet side street?

-

Low-Traffic Areas: Roads and parking lots with minimal vehicle flow do not require the most durable (and expensive) paint options. Standard cold-applied paints are often sufficient.

-

High-Traffic Areas: For highways, busy intersections, and commercial zones, investing in a highly durable paint like thermoplastic or epoxy is more economical in the long run, as it significantly reduces the need for frequent re-striping.

2. What Are the Local Climate Conditions?

Weather plays a significant role in the performance and lifespan of traffic paint.

-

Temperate & Dry Climates: In regions with mild weather and low precipitation, less-resistant paints can perform adequately.

-

Harsh Climates: If the road surface will be exposed to heavy rain, snow, ice, and de-icing salts, you must select a highly durable and weather-resistant paint. The expansion and contraction of the pavement due to temperature changes also demand a flexible and robust marking material.

3. How Important is Retroreflectivity?

Retroreflectivity is the ability of the paint to reflect a vehicle's headlight beams back to the driver, making the markings visible at night and in adverse weather. This is a critical safety feature.

To achieve this, glass beads are applied to the paint while it is still wet. These beads embed into the paint's surface and act as tiny reflectors. Municipalities and government agencies have strict standards for minimum retroreflectivity levels. Ensure you are aware of any local or national regulations for your project to select a paint system that meets these legal requirements.

4. What is Your Project Budget?

Like any product, traffic paints vary widely in price. The total project cost includes not only the material itself but also the specialized equipment and labor required for application. Always consider your available budget when selecting your paint type. While a cheaper paint may save money upfront, it could lead to higher costs over time due to the need for more frequent re-application.

Cold Applied Traffic Paint: Types and Uses

Cold applied paints are applied at ambient temperatures without the need for heat. They are versatile and come in several formulations.

Solvent-Based Paints

The primary advantage of solvent-based paint is its low freezing point, allowing it to be applied in colder weather where water-based paints would fail. Oil-based varieties are common due to their versatility and low cost. However, they contain Volatile Organic Compounds (VOCs), which have environmental restrictions in some regions, leading many to prefer water-based alternatives.

-

Acetone-Based Paints

-

This sub-type is excellent for application in early spring, late fall, and even winter months. It's a popular choice for parking lots. Its main drawback is that cleanup requires acetone, an environmental pollutant.

Water-Based Paints

As the "greenest" option, water-based paints are environmentally friendly and the most cost-effective type on the market. They dry quickly in warm, low-humidity conditions. Cleanup is simple and requires only water.

The main weakness of water-based paint is its poor performance in low temperatures. It cannot be applied in temperatures at or below 50°F (10°C). This limits the striping season in colder climates. It is also the least durable option among traffic paints.

Two-Component (Epoxy) Paints

First introduced in the 1970s, two-component epoxy paint is formed by mixing a resin and a catalyst. This chemical reaction creates an incredibly durable and chemical-resistant finish with powerful adhesion, especially to concrete surfaces.

Due to its high durability and resistance to abrasion, epoxy is ideal for high-traffic highways and freeways. It can last for over four years and be applied in temperatures as low as 35°F (2°C). However, it requires specialized, expensive mixing and application equipment, which increases the overall project cost.

Hot Applied Traffic Paint: Types and Uses

Hot applied paint, or thermoplastic, is a thick, durable material that is heated before application and bonds to the pavement as it cools.

Thermoplastic Paint

As the name suggests, this material contains plastic polymers. It is the gold standard for durability and is the most common choice for highways, freeways, and high-traffic intersections. Thermoplastic markings can be applied in several ways:

-

Extruded or Ribbon: A thick, raised line is applied to the road. At 90 mils (0.09 inches) or more, these lines are highly durable and offer excellent retroreflectivity.

-

Spray: A thinner layer (around 60 mils) is sprayed onto the surface. This is faster and uses less material but is slightly less durable than extruded lines.

-

Preformed Thermoplastic: The material comes in pre-cut shapes, letters, and symbols (e.g., arrows, bike lane symbols, handicap logos). These are laid on the pavement and heated with a torch until they melt and fuse with the surface.

Thermoplastic is one of the most durable and long-lasting road marking solutions, with a service life of many years.

Pavement Marking Tapes

These are heavy-duty, pre-formed tapes that are applied to the road surface.

-

Temporary Tapes: Designed to be removed easily, they are often used in construction zones to redirect traffic and are removed once the project is complete.

-

Permanent Tapes: These offer a durable marking but are generally used in lower-traffic areas compared to thermoplastic. They are applied using a heat torch to bond the adhesive to the pavement.

Application Methods and Equipment

The application process varies significantly between hot and cold paints.

-

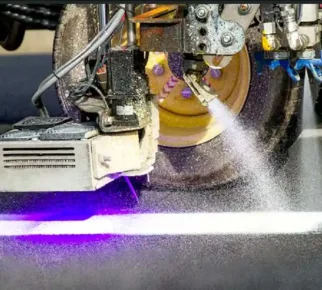

Hot Applied (Thermoplastic): Requires specialized machinery, including a kettle or melter that heats the material to approximately 400°F (200°C). The molten liquid is then applied to the road, where it cools and hardens into a solid line.

-

Cold Applied: Can be applied with simpler equipment, ranging from large truck-mounted sprayers to smaller walk-behind stripers. For very small jobs, it can even be applied with a brush or roller.

Applying Retroreflective Glass Beads: For markings to be visible at night, glass beads must be applied. This is done with a specialized bead dispenser on the striping machine or, in some cases, by hand. The beads must be dropped at a precise rate to embed properly into the wet paint, with about 60% of each bead exposed to catch and reflect light.

Conclusion: Choosing the Right Paint for Your Project

Based on the factors discussed, here are our recommendations for the most common projects:

1. Best for Parking Lots

For most parking lots, water-based traffic paint is the ideal choice. It is low-cost, fast-drying, and environmentally friendly. Since parking lots do not experience the high-speed, heavy wear of a highway, the superior durability of more expensive paints is not necessary.

-

Exception: In very cold climates, a solvent-based paint may be required for application during colder months.

2. Best for Highways and Freeways

The markings on highways must be exceptionally durable and reliable. Thermoplastic and two-component epoxy are the best options. They withstand high speeds, heavy traffic loads, and harsh weather, offering a long-lasting and safe result that justifies the higher initial investment.

3. Best for Secondary / Rural Roads

While some might argue these roads need less attention, traffic laws and safety requirements still apply. Since traffic volume is lower, a highly durable material isn't always necessary. Water-based paint is often sufficient and cost-effective.

However, a crucial factor for these roads is visibility, as they are often poorly lit. Therefore, it is essential to invest in a high-quality application of retroreflective glass beads to ensure markings are clearly visible to drivers at night

At Arazshimi Fam, we understand the importance of safety and durability in traffic projects. Our team is ready to provide expert consultation to help you choose the best traffic paint and implementation materials for your specific project. For more information and to explore our products, please contact us.