Glow-in-the-Dark Paint: Technology, Implementation, and Challenges

Introduction

In an era where road safety is a global priority, innovative technologies like glow-in-the-dark road paint (also known as photoluminescent road paint) offer a promising solution to enhance visibility at night. This specialized paint absorbs light during the day and emits a soft glow in darkness, aiding drivers, cyclists, and pedestrians in low-light conditions. Araz Shimi Fam, a leader in traffic paints, epoxy, and chemical materials, presents this comprehensive guide to glow-in-the-dark road paint. This article explores the technology, its implementation, leading manufacturers, benefits, drawbacks, and the reasons why this technology has not become widespread. If you’re searching for a definitive resource on this topic, you’ve found it.

What is Glow-in-the-Dark Road Paint?

Glow-in-the-dark road paint is a type of traffic paint infused with photoluminescent materials that absorb light (from the sun or artificial sources) during the day and emit a pale yellow-green glow at night. Unlike retroreflective paints, which reflect light from vehicle headlights, this paint glows independently, making it ideal for areas without street lighting, such as rural roads, bike paths, or pedestrian crossings.

The paint comes in various forms:

-

Solvent-Based Paint: Durable and suited for outdoor roads, e.g., Stardust Colors’ ST1041.

-

Water-Based Paint: Eco-friendly and used in some regions.

-

Thermoplastic Paint: Weather- and wear-resistant, blending photoluminescent pigments with thermoplastic materials.

According to ISO 17398 standards, the glow performance is classified based on layer thickness (e.g., Class C for 100µm dry, Class D for 150µm dry).

Technology Behind Glow-in-the-Dark Road Paint

The core technology relies on photoluminescent materials, typically europium-doped strontium aluminate, which:

-

Absorbs Light: Captures UV light during the day.

-

Stores Energy: Converts and stores it as phosphorescence.

-

Emits Light: Releases a green-yellow glow for 6-8 hours in darkness, depending on light exposure and layer thickness.

This process requires no electricity or batteries, and the phosphorescence lifespan is theoretically unlimited without performance degradation. However, the glow is subtle and only effective in complete darkness, as ambient light (e.g., from streetlights or the moon) can diminish its visibility.

The paint is typically two-component: a resin base mixed with photoluminescent powder (3:1 ratio by weight). The mixture remains usable for up to a year. For enhanced reflectivity, transparent retroreflective microbeads can be applied over the phosphorescent layer, though this requires a white undercoat for optimal effect.

History and Pilot Projects

Glow-in-the-dark road paint isn’t new. Early experiments began in the 2010s. In 2014, BBC News reported on a pilot project in the Netherlands (N329 road near Oss), led by Heijmans and artist Daan Roosegaarde. The goal was to replace streetlights with glowing road markings. The paint, containing photoluminescent powder, glowed for up to 8 hours.

However, the project failed due to the paint’s sensitivity to moisture from heavy rainfall, which caused inconsistent glow performance. Engineers planned a “Glowing Lines 2.0” version for the following summer, but widespread adoption never materialized. In 2022, a Reddit post highlighted an Australian company’s similar technology, but user discussions emphasized that retroreflective paints are cheaper and brighter. Tests in Europe and the US have focused on bike paths, not major highways, due to practical limitations.

Companies Producing Glow-in-the-Dark Road Paint

Several companies lead in this niche market:

-

Stardust Colors (France): Offers PH1041, a solvent-based acrylic polyurethane paint applied over a white undercoat (ST1041). Available in kits (1.33kg to 26.6kg), starting at approximately €91.80. Source

-

Glowup (China): Specializes in photoluminescent powders and paints (solvent- and water-based). Emphasizes non-toxic, eco-friendly products compliant with EU REACH regulations. Recommends yellow-green pigments with 20-40% powder dosage. Source

-

Heijmans (Netherlands): Conducted the Dutch pilot and continues R&D.

-

Other players include unnamed Australian firms and Chinese suppliers of raw photoluminescent powders.

In Iran, companies like Araz Shimi Fam could adopt this technology through imports or local production.

Implementation and Application Process

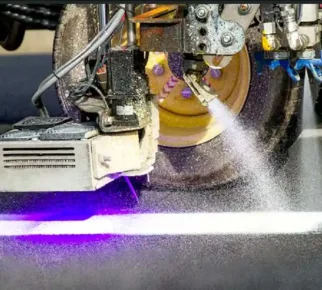

Applying glow-in-the-dark road paint is similar to standard traffic paint but requires precision:

-

Site Selection: Choose dark areas without artificial lighting (e.g., rural roads, bike paths).

-

Equipment: Use standard road marking machines with a 1.5-2mm nozzle. Thermoplastic paints require heating equipment.

-

Surface Preparation: Ensure the surface is clean, dry, and grease-free. Apply a white primer for better reflection.

-

Paint Application: Stir thoroughly to distribute photoluminescent pigments. Apply two layers (200g/m² each, 150-250µm wet thickness) with 20-30 minutes drying time between layers. One kilogram covers 2-2.5m² (e.g., 15m for a 15cm-wide line).

-

Optional Reflectivity: Add retroreflective microbeads for combined effects, requiring a white base.

Advantages and Disadvantages

Advantages:

-

Enhanced Safety: Reduces accidents in dark areas (over 40% of crashes occur in low-light conditions).

-

Energy Efficiency: No electricity needed, eco-friendly.

-

Durability: Unlimited phosphorescence lifespan, fast-drying.

-

Versatility: Suitable for roads, bike paths, parking lots, and pedestrian areas.

Disadvantages:

-

Moisture Sensitivity: Rainfall reduces glow consistency, as seen in the Dutch project.

-

Weak Glow: Only effective in complete darkness; headlights or ambient light wash it out.

-

High Cost: More expensive than retroreflective paints.

-

Durability Issues: Susceptible to photobleaching (degradation under sunlight) and road wear.

-

Environmental Concerns: While modern powders (e.g., Glowup’s) are non-toxic, older formulations raised toxicity concerns.

Why Isn’t Glow-in-the-Dark Road Paint Widespread?

Despite its appeal, several factors limit its adoption:

-

Performance Gaps: Internet images exaggerate the glow; in reality, it’s faint and lasts until midnight only in complete darkness.

-

Better Alternatives: Retroreflective paints are cheaper, brighter, and directional (e.g., red reflectors signal wrong-way driving).

-

Technical Challenges: Moisture sensitivity, wear, and need for total darkness.

-

Cost and Maintenance: High initial costs and frequent reapplication.

-

Regulatory Hurdles: Agencies like the UK Highways Agency deem it unsuitable due to poor daytime visibility, skid resistance, and winter performance.

Discussions on the Internet suggest that it’s more practical for pedestrian or bike paths than highways.

Conclusion

Glow-in-the-dark road paint is an innovative solution with potential to improve safety in unlit areas, but technical and cost barriers have prevented widespread use. Araz Shimi Fam is ready to assist with implementing this technology. Contact us for more details.

Sources: