Application of two-component and three-component paint

In this article, we explore the applications of two-component and three-component paints, which are among the most popular choices in traffic and construction industries. These paints stand out for their high durability and resistance to environmental factors, making them ideal for various surfaces. If you're looking for detailed info on usage, benefits, and key execution tips, keep reading.

What is Two-Component Paint?

Two-component paint typically combines polyisocyanate with a base color, resulting in an extremely resistant coating against corrosion and chemicals. These belong to the epoxy family and consist of two main parts: the base paint and a hardener. For optimal results, mix these components in the exact ratio and apply immediately after mixing to avoid losing the working time.

Uses of Two-Component Paint

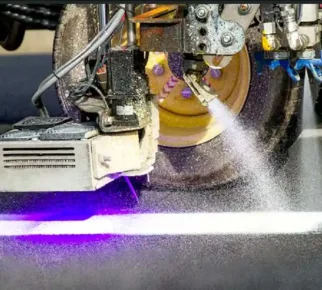

This paint has diverse applications, including traffic lines, pedestrian crosswalk markings on asphalt, pool painting, and even thick layers for roadside warning signs. Thanks to its excellent adhesion, two-component paint is perfect for surfaces exposed to heavy wear and pressure.

Factors Affecting the Quality of Two-Component Paint

If the substrate isn't properly cleaned—containing sand, dust, or moisture—the paint's long-term durability decreases. Additionally, applying it too thin or in low-thickness layers reduces its resistance. Always ensure the surface is fully dry and clean before application.

What is Three-Component Paint?

Three-component paint consists of three main parts: the base paint, a reaction accelerator (often acting as a solvent), and a hardener. To prepare, combine these in specified ratios for a uniform mixture.

- Pigments: Fine mineral or organic powders that provide color, opacity, film cohesion, and sometimes corrosion inhibition.

- Solvents: Organic liquids or water that ease the painting process.

- Hardener: Typically resin or oil, but inorganic compounds like soluble silicate may also be used.

Uses of Three-Component Paint

This paint is ideal for pedestrian crosswalks, parking lot signs, high-traffic area markings, street center lines, highways, freeways, road signs, and airport lines. Due to its quick drying and high resistance, it's widely used in large traffic projects.

Factors Affecting the Durability of Three-Component Paint

To maintain quality, ensure not only dry weather but also a completely dry and contamination-free surface (like dust, oil, or grease). Following these ensures significantly longer lifespan.

Overall, multi-component paints—categorized under traffic paints—are the best choice for metal and concrete surfaces due to their superior adhesion. If you're seeking high-quality products, Araz Shimi Fam, as a producer of durable epoxy, two-component, and three-component paints, offers a variety of options. Click to View our products